Mazda Researchers receive two Awards for exceptional Achievements in Automotive Engineering

- Mazda engineers honoured for improving diesel particulate filter (DPF) technology

- Second award for world-record compression ratio and reduced friction in petrol engine

- Mazda's new-generation petrol praised as example of future, ultra-efficient engine

Mazda Motor Corporation engineering teams were honoured today with two Technological Development Awards at the 62nd Society of Automotive Engineers of Japan (JSAE) awards ceremony in the Yokohama Convention Centre. One group of Mazda researchers was recognized for improving diesel particulate filter (DPF) performance, another group for achieving a world-record compression ratio - and lowering friction for improving fuel consumption - in Mazda's new SKYACTIV-G petrol engine. The JSAE award is given in recognition of outstanding new products or technologies that contribute to the development of automotive engineering.

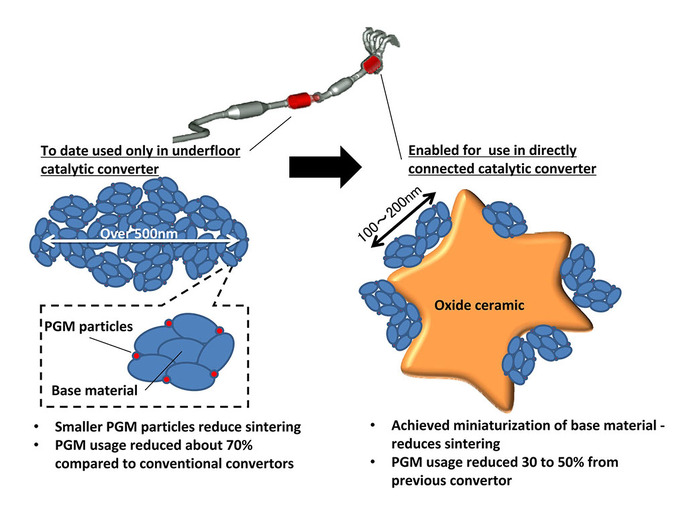

One award is for improvements to Mazda's single-nanocatalyst technology* including enhanced thermal durability and low-temperature performance. This technology is applied to the DPF of Mazda's new-generation SKYACTIV-D clean diesel engine used in the Mazda CX-5. These improvements allow the technology, which was previously employed only in the underfloor catalytic converter, to be used in the converter attached directly to the engine. It also achieves a 30 - 50% reduction in the use of rare platinum group metals (PGM) without a diminishment in peak performance.

The second Technological Development Award is for two revolutionary achievements in internal combustion technology. This group of Mazda researchers achieved a compression ratio of 14.0:1** - the highest in the world for a mass-produced petrol car engine - with the new-generation high-efficiency direct-injection SKYACTIV-G petrol. The reward also recognizes improvements in fuel efficiency realized via a thorough reduction of mechanical friction and pumping loss.

* This unique Mazda technology avoids the decline in performance associated with the sintering of precious metal particulates by embedding particles less than five nanometers in length (single nano sized) into a specially developed base material. (1nm=0.000001mm) http://www.mazda.com/publicity/release/2009/200901/090108a.html

** As of May 2012 (Mazda data)

Diskusia k článku

Najnovšie galérie

Bianka

Bianka

Jan

Jan

Martin

Martin  Per

Per

Juha

Juha